| Coating |

|

|

|

| Honest-A series |

Honest-B series |

Honest-C series |

|

Honest-A is a coating material directly used in tablets, droplets and pellets, which make the solid dosage forms obtain stable mechanical properties, and giving the effects of anti-moisture, light-prevention, anti-oxidation with perfect appearance.

A-1- Efficient Film Coating Systems

A-2 –Separated Film Coating Systems

A-3 Regular Film Coating Systems

A-4- Lozenge Film Coating Systems

A-5- Moisture Barrier Film Coating Systems

A-1

formula

The addition of film-forming homopolymer with micro-molecular weight decreases the standard viscosity of the coating materials, and facilitate atomization and be more easy to operate.

properties

The shortened coating time, high efficiency and low requirements to the tablets quality.

Application features

Moisture Barrier Function: Provide efficient protection to drug unless the tablet is specially humid-sensitive or contains the strong volatile ingredient.

Appearance: The tablet with standard requirements can obtain exceptional appearance.Standard Viscosity: The viscosity is about one-tenth of the value of the regular type, which increase the solution concentration and the film-forming velocity. Have good suitability to various types of tablets. For example, on the large extent avoid intagliation bridging, and with less amount of aqueous solvent entry in the coating process.

A-2

The formula

Separated Film Coating adopts various kinds of film formation polymers.

properties

A-2 Separated Film Coating can strongly prevent the volatile substance of the drug seeping out. The larruping performance is better than the normal coating products.

Application features

1. To prevent the volatile components seeping out, and make the effective ingredients of the drug keep stable.

2. To mask taste and odor, easing the mental fear when taking the medicine.

3. The core absorbing moist is reduced, in the meantime, prevents the oil ingredients contained in traditional Chinese medicine seeping out from the membrane, which guaranteed the perfect appearance and prolonged validity period.

4. Adopting water as solvent that facilitate coating operation. Containing no organic solvents that save the cost and comply with the GMP Standard.

A-3

The formular

Using HPMC as film forming materials, which makes it have good solubility and perfect mechanical properties.

properties

It is the best choice to obtain perfect appearance and tensile strength of coating film.

Application features

The characteristic of A-2 Regular-Coatings is the perfect balanced properties, and it is the best product in A series which can apply to different tablet cores.

A-4

The formula

The oligomerized carbohydrate & cellulose adopted to form film improve the velocity of film solubility; no unusual odor, decrease the film feeling;

properties

The soluble velocity in water of the lozenge type coating agents is more than twice of the value of the normal coating agents. Under saliva environments melting rapidly, would ease the film feeling.

Application features

1. Good adaptability. By using different proportional solvents, such as 100% aqueous solvent system or hydro alcoholic solvent system to protect the water-sensitive drug with high-sugar ingredients.

2. Different solvents can be used. Oil-soluble or water-soluble flavor can be added as flavoring agents to achieve various flavors.

3. Adding flavoring agent to the film formula in according to the flavor of the lozenge drug to improve the taste, in the meantime, obtain the same flavor of the drug.

4. The perfect anti-moisture properties solve the problems of softening and picking.

A-5 solvent: (80% - 95% Ethanol)

formula

The hydrophoby polymer in the aqueous moisture barrier coating agent which form crystal when combine with HPMC, increases the degree of coalescence, and have a good function to restrain effectively water permeation.

tproperties

Have a good shield function to the atmospheric moisture, and protects the tablet from atmospheric moisture, which make honest-A have supernormal anti-moisture properties.

Appliaction features

As an aqueous coating agent,honest- A Moisture Barrier-Coatings have a limited anti-moisture function to the tablets, and the limitation is dependent on if the final result meets the quality requirement to the tablets or not.

Separated Function: On the basis of keeping disintegration fast in the stomach, it extensively reduce the water vapor permeation, the possibility of cracking, inflation and deformation, the quality changes in the humid and hot conditions.

Appearance: The color is not affected by the absorbing humidity ingredients in the drug, which makes the color stable in the long period and the film has a moderate smooth finish.

Honest-B

B Sustained Release Coatings is one of the most popular aqueous polymeric dispersion which classified as psuedolatex to prepare the sustained release oral dosage forms by film-controlling. It forms a coating film that of sustained release function, which makes the dosage forms release the drug continuously.

? B-1(Professional Type)

? B-2 (Regular Type)

The formula

Honest B is an aqueous controlled/sustained release polymeric coating system, which takes Ethyl Cellulose (EC) as polymer.

Main features

1. Aqueous solvents system without organic solvents

Aqueous solvents system eliminates the inflammability, explosion and toxicity of the organic solvents, which complied with GMP Standard, be safer to use as well as protect the environments;

2. High concentration and low viscosity

When solid content is at 30%, the aqueous dispersion is of fairly low viscosity. Compared with other aqueous coating agents, the honest-B has the properties, which can operate under high concentration conditions, film-forming velocity is fast, and coating time is short.

3. Perfect operation properties

Low viscosity of the coating solutions avoids the phenomenon of sticking that commonly exists in organic solvents system with high concentration.

4. Better Suitability

Extensively used in preparation of sustained release pellets, sustained release tablets, moisture barrier/ sealer of solid dosage forms and flavor masking & granulating by damp method.

B-1 (Professional Type)

The formula

B-1(Professional Type) is aqueous ethyl cellulose dispersion with about 30% total solid content prepared by direct emulsion solvent evaporation method.

Application properties

B-1 (Ethyl Cellulose Dispersion) singlely used for coating can not obtain good drug release effects. In order to get optimal release requests, in addition to take the properties of the drug itself, the layer thickness, plasticizers and additives added into the coating suspension should also be considered.

1. Plasticizer

When using B-1 (Ethyl Cellulose Dispersion), proper plasticizer (such as, DBS, TEC, DEP, etc.) shall be chose according to the release requirements of the drug. The plasticizer suggested adding into B-1 is DBS, and the suggested added amount is20-25% of the solid content.

2. Pore former

Pore formers are mainly some surfactants, water-soluble small molecular and or film forming materials. The addition of the pore formers can affect the permeability of film formed by B-1 and fasten the drug release rate.

3. Anti-adherent

To avoid drug particles sticking affecting coating effects during operation, proper amount of anti-adherent (such as, Talc, etc.) and inorganic colorants (such as, pigments, Titanium Dioxide, etc.) can be added. B-1 can compatible with ethanol-dispersed colorants. First add plasticizer and stirring for 2 hours and then add colorant is recommended. Also, do single color coating out of the B-1film is applicable.

B-2 (Regular Type)

The formula

B-2 (Regular Type) is an aqueous sustained release coating system, which using Ethyl cellulose as release rate controlling polymer.

Application properties

1. Stable release rate and perfect reproducibility.

2. Drug release is achieved by diffusion through the B-2 film, and is directly controlled by the thickness of the film. The release rate can be effectively adjusted by simply increasing or decreasing the quantity of B-2 applied.

3. The perfect film form by B-2 dispersion provides consistent release rate and effective sustained release function.

4. Stable properties of materials, optimal formulation and high product quality complied with USP Standards, all of these guarantee the use safety and environments protection

Honest C

Honest C is the kind of pH controlled polymeric coating materials which are used for enteric coating.

C-1

C-2

C-3

Main Features

Polymeric membrane can keep as integrated under a physiological environment with a low pH value (such as gastric fluids), which effectively prevent drug release from the drug release system.

When drug enters into a high pH environment (such as small intestine), the film is able to dissolve fast as per the time and position planed in advance, and then rapidly release the drug.

It is able to coat the hydrophilic tablets or tablets with acid-sensitive ingredients.

Effectively improves the appearance and stomach-resistance properties of the dosage forms, meanwhile, decreases the possibility of cracking.

In the coating process, the coating suspension is not easy to condense and is of good leveling property.

The adhesion between membrane and tablet core is good.

Be able to do color coating with colorful and stable color.

C-1 solvent:80% Ethanol

The formula

C-1 takes HPMC as main material, and adds plasticizer, pigments and various kinds if additives.

Application properties

1. With low dissolution pH value, the membrane can dissolve fast when pH value is above 5.5; Faster drug release, and high organism utilization ratio, be suitable for special pharmaceutical dosage forms.

2. The membrane is stable in the stomach, dissolve fast when entering into the intestine, which guarantees an effective and safe drug release in intestine fluids.

3. HPMC is of perfect store stability, and its free acid contents with unapparently changes during the long period storage shows little affects to drug release and absorption. The test below shows the free acid contents changes of HPMCP & CAP at the 40??/80%RH unpacked condition, from which we can know the stability of HPMCP is higher than CAP's.

C-2 solvent:75%-80% Ethanol

The formula

The formula be on basis of Methacrylic acid copolymer protects the drug from eroding by acid medium, and simplify the coating process.

Mail features

1.C-2 provides low viscosity, full atomization in operation and perfect appearance. The high mechanical strength of the film provides a perfect protective function to tablet.

2. The adhesion between membrane and tablet core is good.

3. Stable color products with bright-color and unfading are available according to the customers' requests.

Application properties

1. High degree of film compaction with 4% to 6% weight gain can effectively resist to gastric-acid erosion.

2. C-2 films dissolve very easily and faster with case in pH 5.5-6.8 depend on formula design.

3. Due to stable membrane properties of C-2, the anti-gastric acid properties and good solubility in enteric fluids can still be guaranteed during the long period storage or under the storing condition with high humidity & high temperature. Under the 40??? storage stability of the enteric tablets coated with EOBS68 by the dissolution time changes in enteric fluids.

C-3 solvent:pure water

The formula

C-3 Aqueous Enteric Film Coating Systems with fire-new leading techniques can make drug release at all segments of intestine,

Low cost

Compared with most similar products on sale, using C-3 with less weight gain can obtain equal effects, and the materials costs will reduce accordingly.

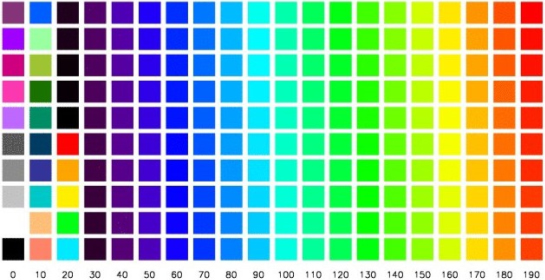

Complete colors are available

Hundreds of standard colors on honest Color Master are for your options; at the same time, the characteristic color matching service is available to satisfy the needs of application and product differentiation improving;

The advanced Color-Data System for color-matching finely guarantees the veracity and stability of colors.

|

|

|

C

O

A

T

I

N

G

|

|

|